Sustainability

Planet-Safe, From Sourcing to Soil

Regenerative Raw Materials

Our story starts with bamboo, nature’s very own carbon capture system. It grows quickly, renews itself naturally, and absorbs up to 17 tonnes of carbon per hectare each year (that’s equal to the annual carbon footprint of nearly 40,000 plastic bottles!)

Did You Know?

Not all “eco-packaging” comes from sustainable sources. Many are made from unrenewable petroleum sources, which pollutes the planet during extraction and processing.

Giving Offcuts a Second Life

Instead of harvesting virgin material or depleting food sources, we use bamboo offcuts from the construction industry that would otherwise be wasted or incinerated.

By using Clement Packaging you are upcycling bamboo, preventing waste, reducing emissions, and supporting a circular economy.

Did You Know?

Plant-based packaging isn’t always more sustainable. Some packaging uses materials like sugarcane, which can divert resources away from the food supply.

Local Sourcing for a Lower Footprint

All of our bamboo and plant-based resins are locally sourced in the same province as our manufacturing facility.

This allows you to minimize your brand’s carbon footprint, provide radical transparency to customers and retailers, and support the regions connected to our materials.

Did You Know?

Post-consumer recycled (PCR) materials are often shipped across the world for collection and recycling. This incurs a hefty carbon footprint hidden upstream in the supply chain.

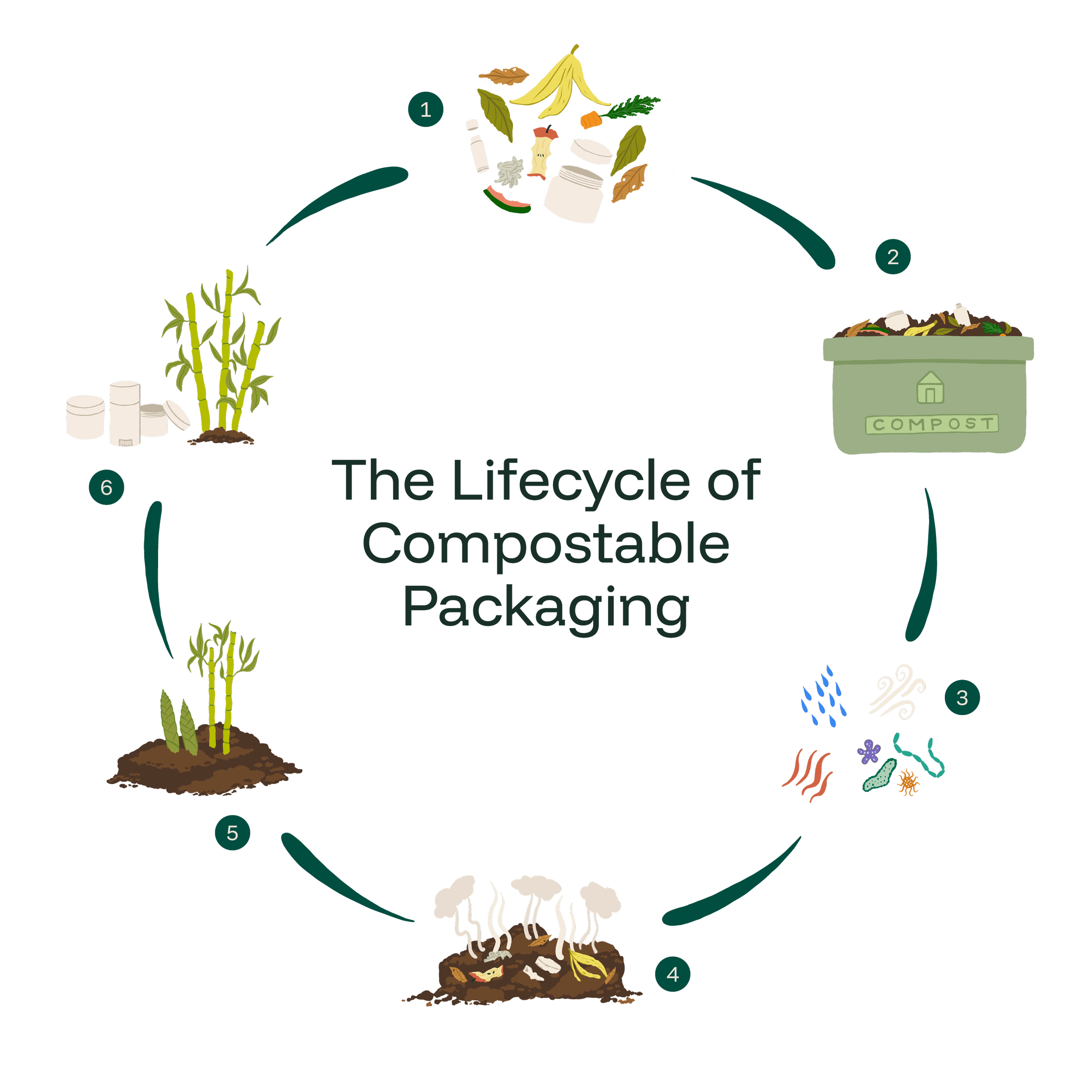

A Clean and Soil-Safe End

Finally, when your product reaches the end of its intended life, it returns to the earth just as gracefully as it began. Our material breaks down fully into nutrients that nourish the soil, to continue the cycle it started with nature.

Did You Know?

Compostable certification is key. Some packaging marketed as plant-based or eco-friendly still contain microplastics, which persist in the environment for thousands of years. Look for packaging that is 3rd party certified to break down quickly and safely.

-

Rules vary by locale, so check with your city. Here are some general tips.

Packaging: look for certified compostable materials. Just because it's green colored or plant-based doesn't mean it will break down!

"Green" waste: nitrogen-rich materials such as vegetables, fruit peels, grass clippings

"Brown" waste: carbon-rich materials such as dead leaves, cardboard, toilet paper rolls

-

Commercially: your city may provide green or brown bins for compost collection at your residential curb or a local farmer's market. "Industrially compostable" materials will breakdown in a commercial facility like this.

At home: start a compost pile in your backyard or kitchen composting machine. Limit this to certified "home compostable" materials.

-

Wonder why your compostable packaging doesn't break down on the shelf?

Composting requires air, moisture, heat, and microbes. Microorganisms help break down the organic material, and these microbes require water and oxygen to function. This digestion process naturally releases heat, which further expedites composting.

-

With the above elements plus time, your organic waste and packaging are transformed into a nutrient-dense soil amendment called compost.

This compost sequesters carbon by storing it in soil, and helps divert organic materials from the landfill where they would otherwise generate methane.

-

Compost is then used to enrich soil like a slow-release fertilizer, helping plants and crops grow healthier and retain moisture better.

This technique is widely used in commercial farming, and you can try it for your home garden too!

-

Finally, plants like bamboo are turned back into bio-based containers at the Clement factory.

The circular process is complete, allowing you to use your favorite consumer products without generating packaging waste or harmful microplastics.